How Custom Sheet Metal Fabrication With Tibah Can Save You Time and Money

Overcoming HVAC Fabrication Challenges: Top 5 Solutions from Tibah Trading in Burlington, Ontario

HVAC fabrication is a critical aspect of the heating, ventilation, and air conditioning industry. From designing and fabricating custom ductwork to creating complex HVAC systems, there are a number of challenges that fabricators face on a daily basis. At Tibah Trading in Burlington, Ontario, Canada, we have encountered our fair share of obstacles in HVAC fabrication, and we have learned how to overcome them effectively. In this blog, we will discuss the top 5 HVAC fabrication challenges and provide practical solutions based on our experience.

1. Lack of Proper Equipment

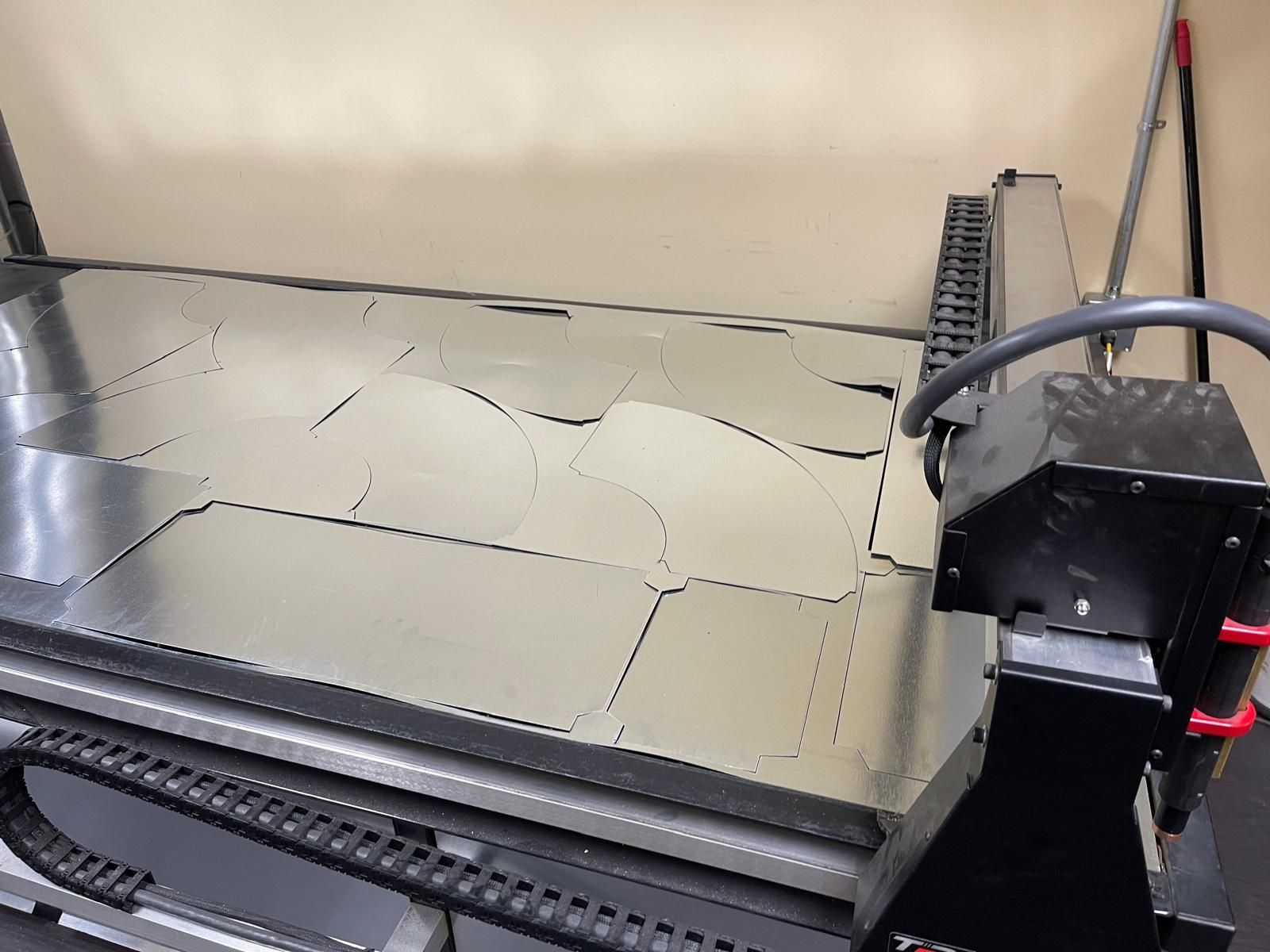

One of the biggest challenges in HVAC fabrication is the lack of proper equipment. Without the right tools and machinery, fabricators may struggle to create accurate and efficient HVAC components. To overcome this challenge, it is essential to invest in high-quality equipment that is specifically designed for HVAC fabrication. At Tibah Trading, we have a state-of-the-art fabrication facility with advanced machinery that allows us to produce top-quality HVAC products.

2. Inaccurate Measurements

Accurate measurements are crucial in HVAC fabrication to ensure that components fit together seamlessly and function properly. However, obtaining precise measurements can be challenging, especially in complex projects. To overcome this challenge, it is important to use digital measurement tools and software that can provide accurate measurements quickly and efficiently. Additionally, taking multiple measurements and double-checking them can help prevent errors in fabrication.

3. Material Selection

Choosing the right materials for HVAC fabrication is another common challenge. The type of material used can impact the performance, durability, and cost of the HVAC system. To overcome this challenge, it is important to work with reputable suppliers who offer high-quality materials that meet industry standards. At Tibah Trading, we have established relationships with trusted suppliers to ensure that we use the best materials for our HVAC fabrication projects.

4. Complex Designs

HVAC systems are becoming increasingly complex, with custom designs and intricate components. Fabricating these complex designs can be a challenge, especially for fabricators who lack experience or expertise in custom fabrication. To overcome this challenge, it is important to work with skilled technicians and engineers who have the knowledge and capabilities to fabricate complex HVAC systems. At Tibah Trading, our team of experienced professionals is equipped to handle even the most challenging fabrication projects.

5. Tight Deadlines

Meeting tight deadlines is a common challenge in HVAC fabrication, as projects often have strict timelines and delivery schedules. To overcome this challenge, it is important to streamline the fabrication process and optimize workflow efficiency. This can be achieved by implementing lean manufacturing principles, utilizing automation and technology, and prioritizing communication and collaboration among team members. By working efficiently and effectively, fabricators can meet deadlines and deliver high-quality HVAC products to their clients.

Facing challenges in HVAC fabrication can be daunting, but with solutions like addressing equipment shortages, ensuring accurate measurements, selecting quality materials, tackling complex designs, and managing tight deadlines, fabricators can produce high-quality products. At Tibah Trading in Burlington, Ontario, Canada, we have the expertise to overcome these obstacles and provide exceptional HVAC fabrication services. Contact us today to learn more about our capabilities and how we can assist with your next project.

All Rights Reserved | Tibah

Website built on the Siphon Sites platform.

2384 Industrial St.,

Burlington, ON L7P 1A1